The process of failure analysis generally refers to the process of simulating the reproduction of the phenomenon of failure, finding out the cause of failure, and excavating the mechanism of failure through analysis and verification according to the failure mode and phenomenon. Device failure is defined as complete or partial loss of function, parameter drift, or intermittent occurrence of all of these conditions.

1. Common Failure Analysis Methods

• Material composition analysis • Physical performance analysis • Solderability analysis

• Dielectric strength • Flammability analysis • Heat resistance analysis

• Corrosion resistance • Resistant to leakage marks

2. Led Common Failure Analysis Methods

• Optical perspective of thinning resin • Semi-corrosive anatomy • Metallographic analysis

• Analytical analysis of factorial tests • Variable current observation method

3. Led Common Failure Analysis Methods

• LED lamp bead failure analysis • Vulcanization failure analysis

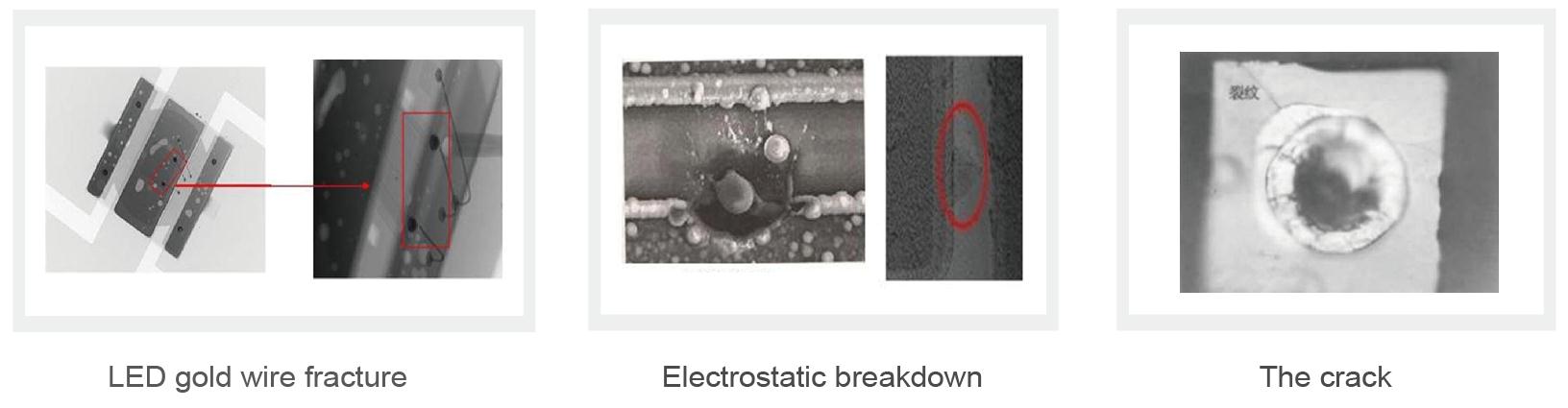

• Chip leakage point lookup • Observation of COB gold wire fracture

• LED gold wire fracture analysis • LED thermal resistance measurement

• Identification of chips • LED excipients sulfur-free component test

• LED anti-vulcanization experiment • LED silicone airtightness check

• Water outlet material identification • LED antistatic ability test

Reliability Failure Analysis Case

CN/中国

CN/中国  US/USA

US/USA  KR/Korea

KR/Korea  DE/Germany

DE/Germany  ES/Spain

ES/Spain VN/Việtnam

VN/Việtnam